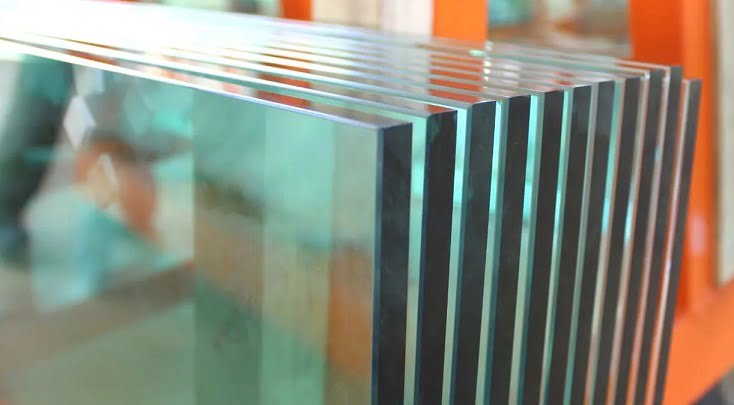

Toughened Glass

Toughened glass, also known as tempered glass, is a type of safety glass that has been strengthened up to five times stronger than regular glass through a special heat and chemical process. It is an excellent choice for high-traffic areas because it can withstand significant impact and pressure without breaking or shattering. When broken, jhuit shatters into small, blunt fragments rather than sharp shards.

We specialise in providing high-quality toughened glass products for a wide range of applications. Whether you need a damaged window replaced or new shower doors installed, we have the expertise and experience to get the job done right. Our professional team is committed to providing excellent customer service and ensuring that you have the best glass solutions for your needs. We are confident that our toughened glass products will meet, if not exceed, your expectations. So, if you require long-lasting and dependable glass products, look no further than our company.

Advantages of Toughened Glass

There are numerous benefits to using toughened glass in a variety of applications. Here are some of the key advantages:

Durability and strength: Toughened glass is up to five times stronger than regular glass, making it highly resistant to damage from impact and pressure. It is an ideal choice for use in high-traffic areas or in situations where the glass may be subjected to significant stress.

Safety in case of breakage: Toughened glass is designed to break into small, blunt pieces rather than sharp shards, making it much safer to use in areas where people or animals may come into contact with the glass, such as in shower doors or low-level windows.

Wide range of applications: Toughened glass can be used in a variety of applications, including windows and doors, furniture and fixtures, shower doors and enclosures, and automotive and transportation. Its versatility makes it a popular choice for many different projects.

Can withstand high temps: Toughened glass can withstand temperatures up to 250 degrees celsius, this makes it ideal for use in environments where it is subjected to high heat.

Cheaper than laminated glass: Both toughened and laminated glass is considered to be grade A safety glass approved as per AS1288 standards, toughened glass is generally 50% cheaper than laminated glass.

Disdvantages of Toughened Glass

While toughened glass has many benefits, it is important to note that it also has some potential disadvantages. Here are a few:

Cost: Toughened glass tends to be more expensive than regular float glass, due to the specialized manufacturing process and additional materials required. This may make it less budget-friendly for certain projects.

Cannot be cut or drilled: Toughened glass will completely shatter when cut or drilled. Any cutting needs to be done BEFORE the glass is tempered.

Limited repair options: If toughened glass becomes damaged, it is generally not possible to repair it. Instead, it must be replaced, which can be costly and time-consuming.

Limited thickness options: Toughened glass is typically produced in 6.38mm due to the constraints of the manufacturing process. Thicknesses outside of this will most likely need to be made to order which can takes a number of weeks depending on the availability. Currently, there is a 2 week lead time for most of our glass suppliers.

How is Toughened Glass Made?

Toughened glass is made through a specialized heat treatment process that strengthens the glass and makes it more resistant to damage. Here is an overview of the process:

- The glass is cut to size and cleaned to remove any dirt or contaminants.

- The glass is then placed in a tempering furnace and heated to a temperature of around 700-750°C.

- Once the glass has reached the desired temperature, it is rapidly cooled using a process called quenching. This process causes the outer surface of the glass to cool faster than the inner core, creating tension within the glass.

- The tension in the glass makes it much stronger and more resistant to breakage.

In addition to the heat treatment process, some manufacturers also use a chemical tempering process to further strengthen the glass. This involves applying a chemical compound to the surface of the glass, which reacts with the surface layers to create additional tension and increase the glass’s strength.

After the toughening process is complete, the glass is thoroughly inspected and tested to ensure that it meets the necessary quality standards. Only glass that passes these inspections is approved for use in various applications.